-

• #2

Would be fun to get updates on the project if you go forward with it 🙂

-

• #3

Sounds like a neat idea!

-

• #4

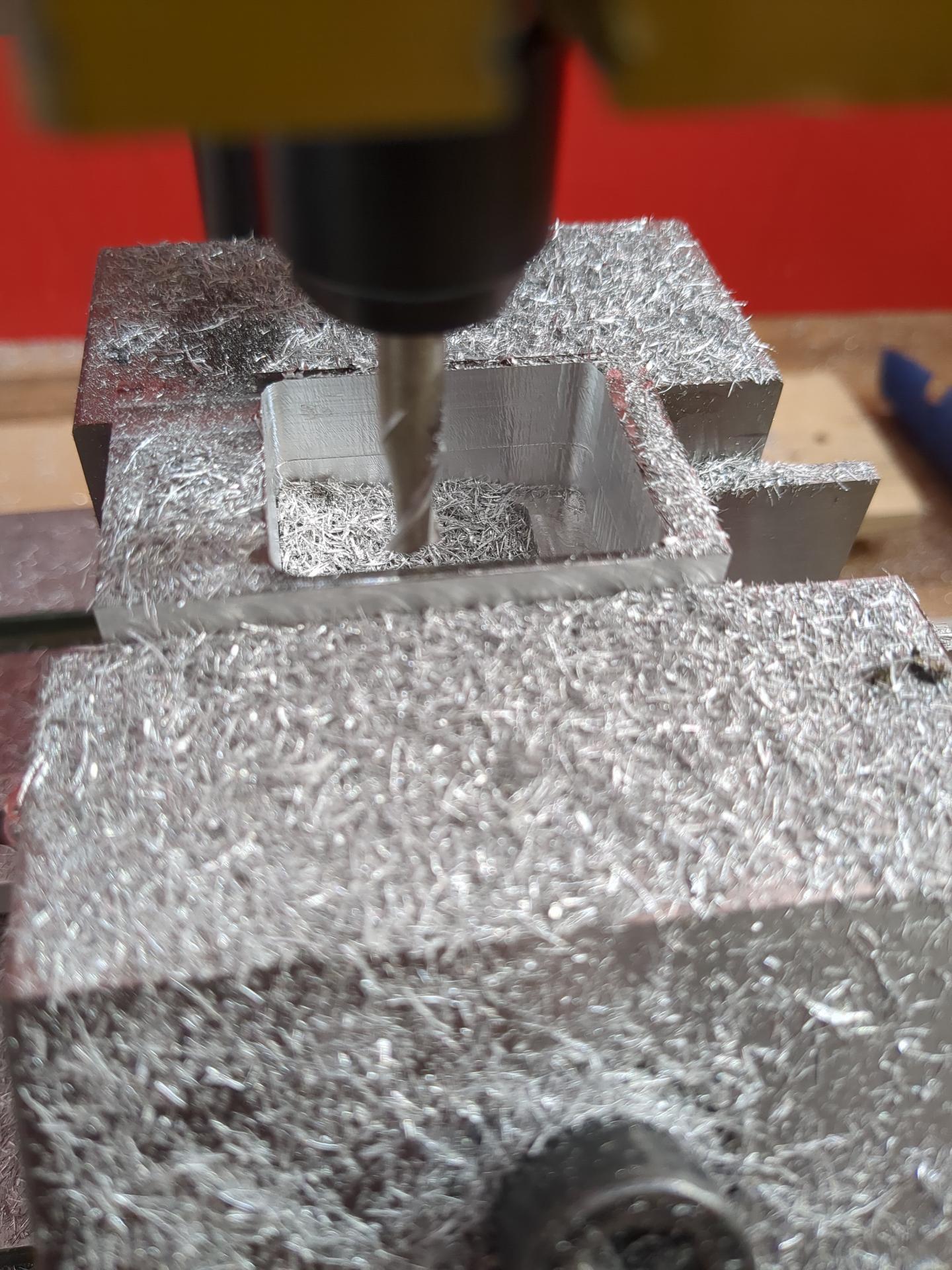

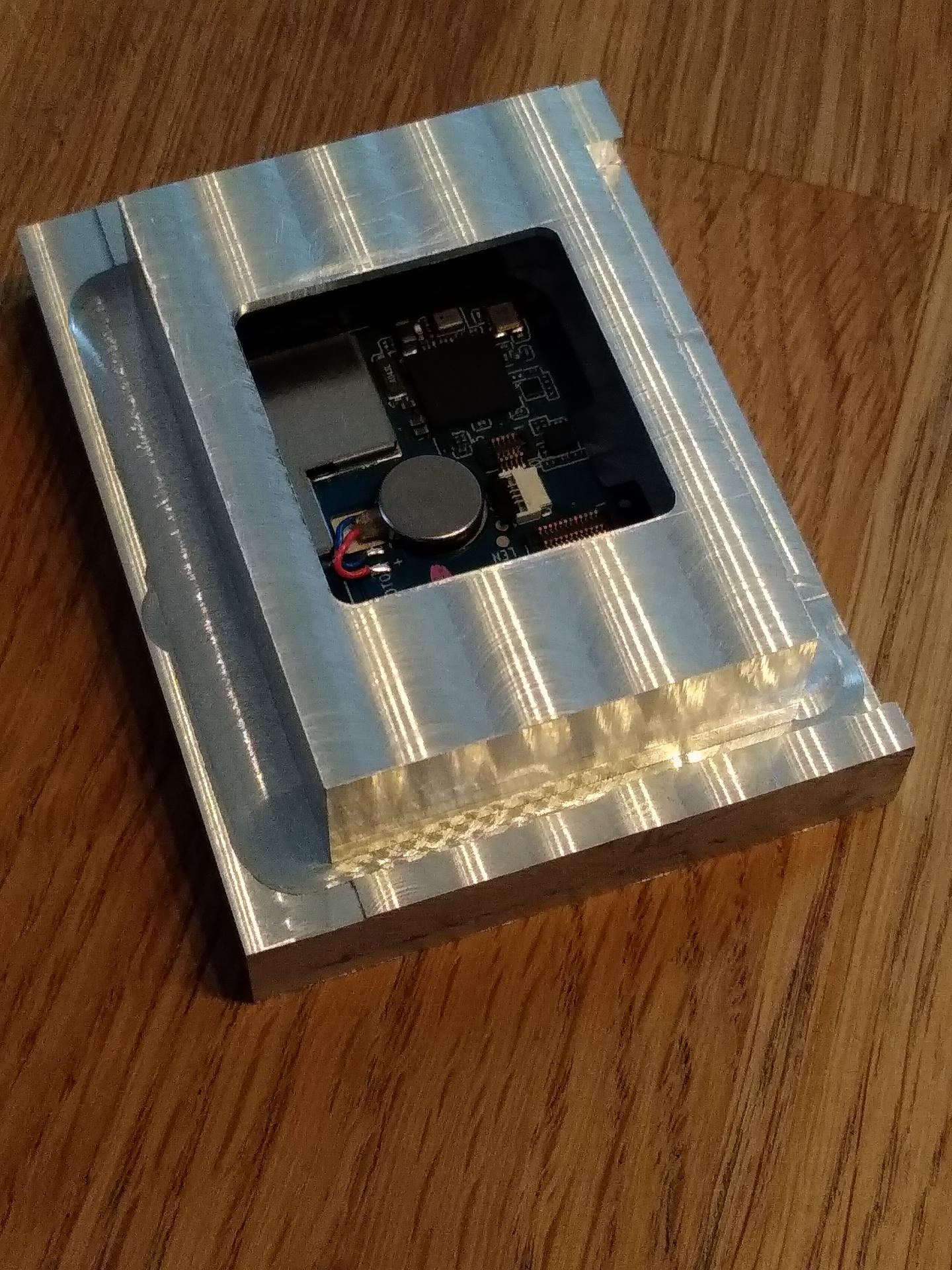

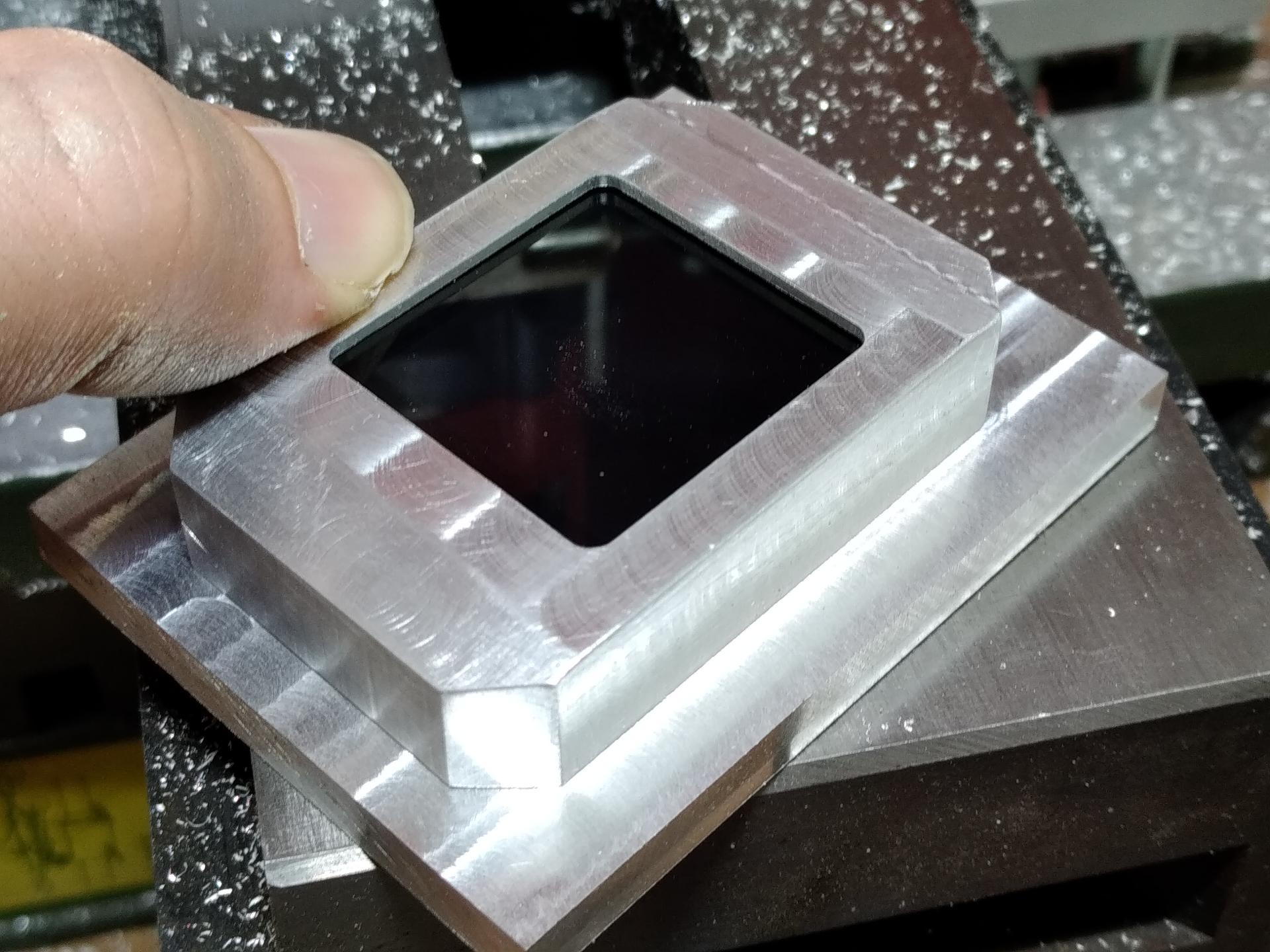

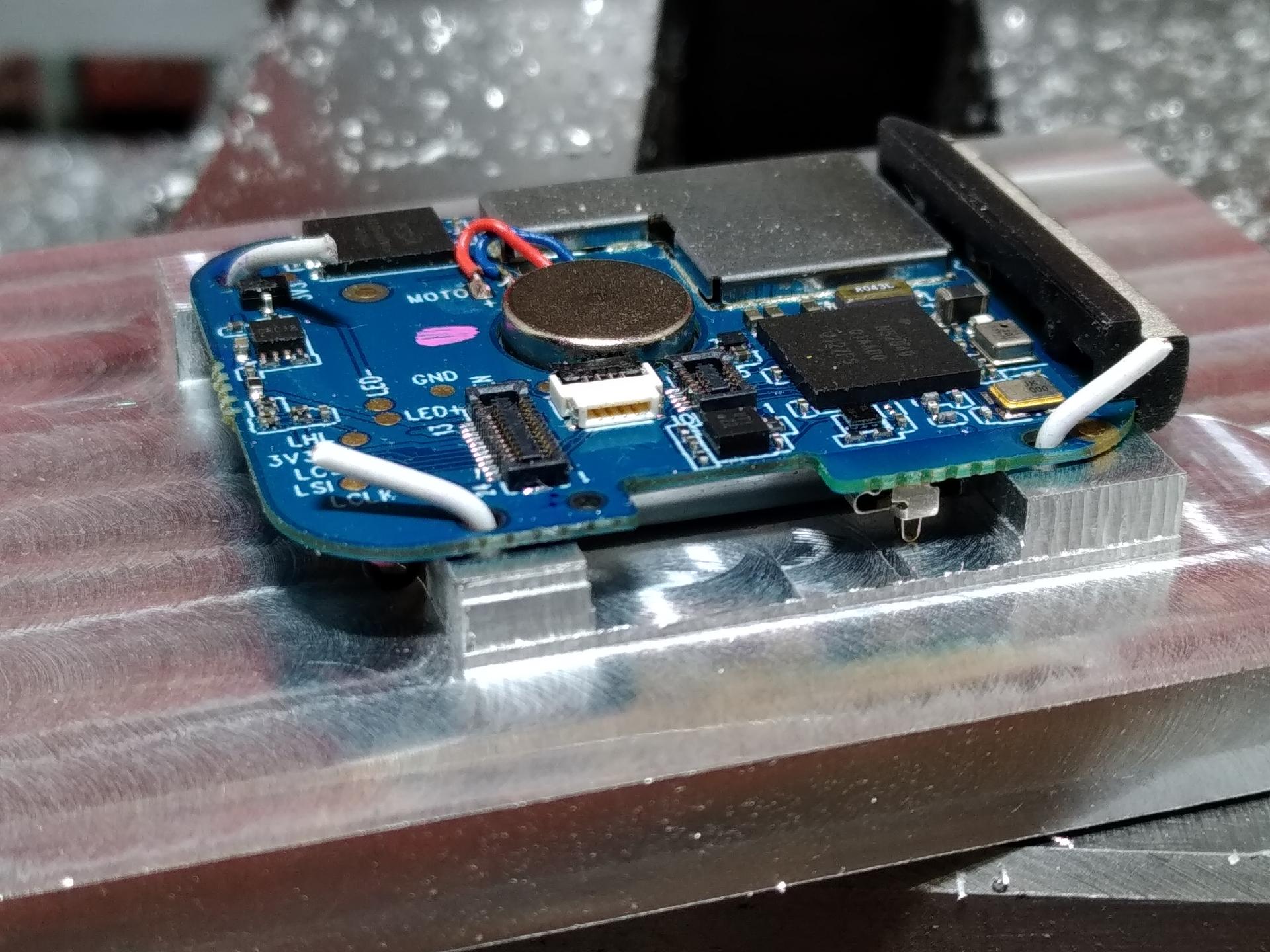

Tried the first few cuts. Went better than expected :)

3 Attachments

-

• #5

Proper engineering stuff, impressive.

-

• #6

Hello,

Interesting, on my watch one of the four holes for the batch is broken, so perhaps I will build your new case as well.

Minnten

-

• #7

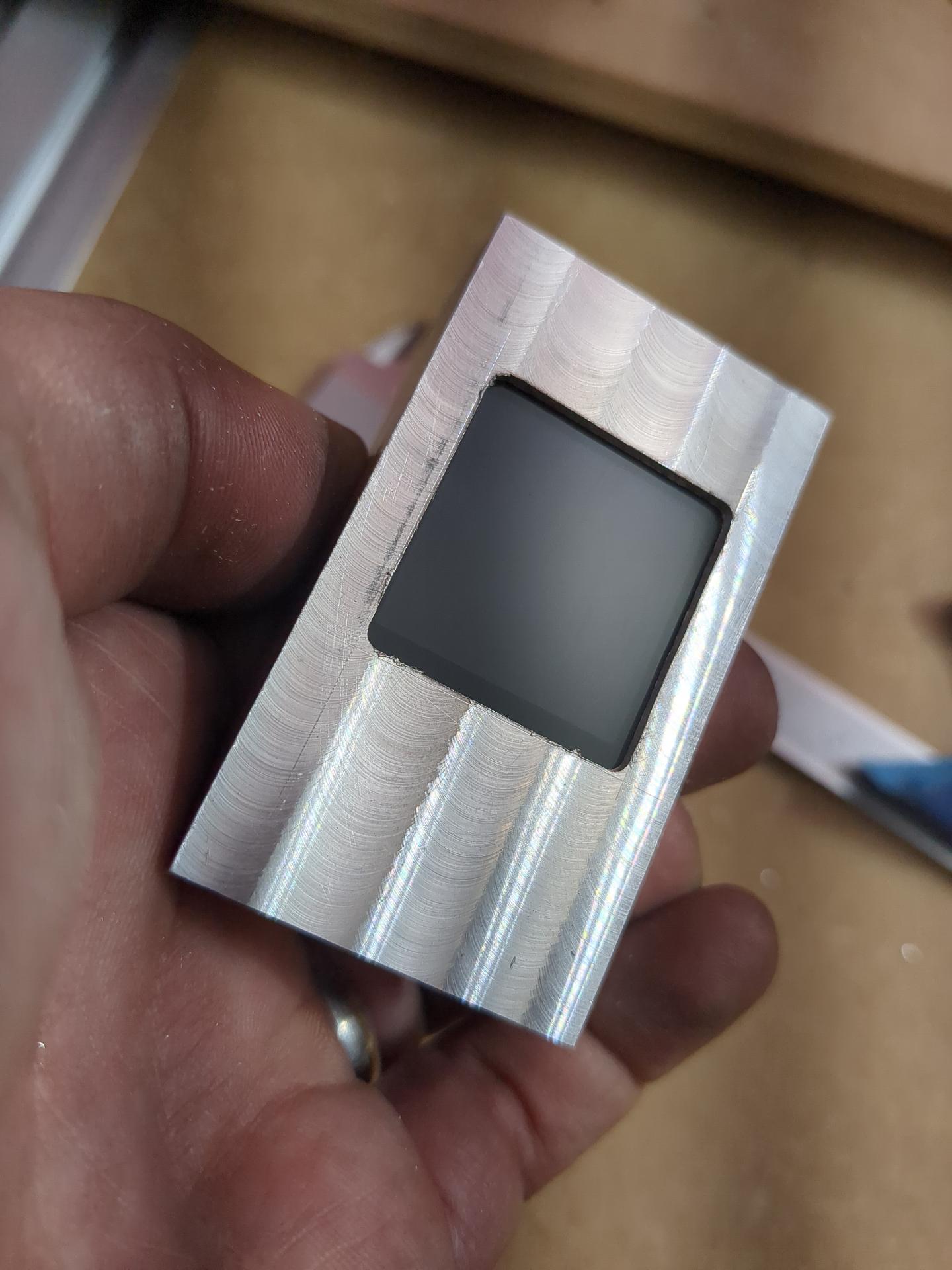

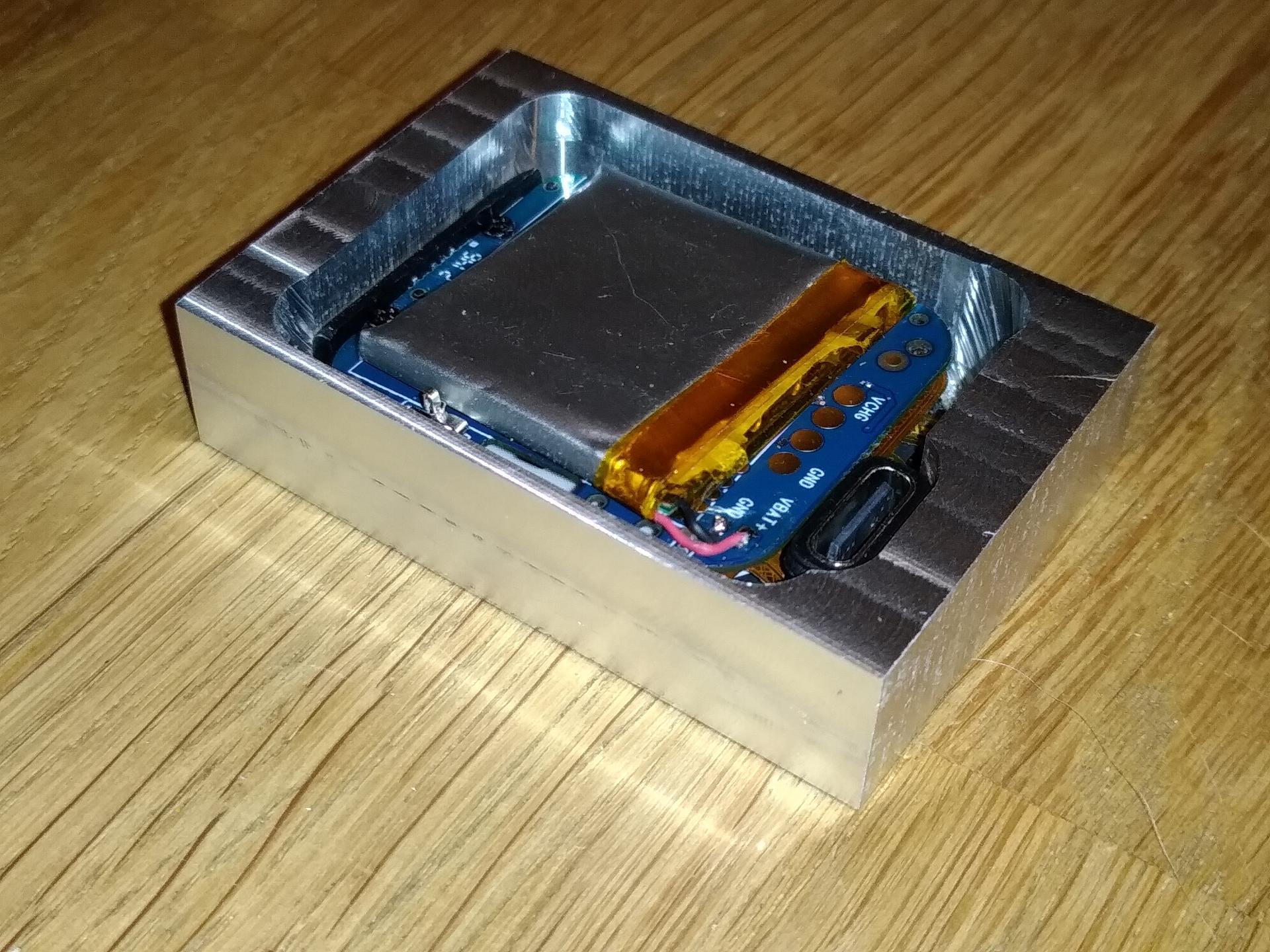

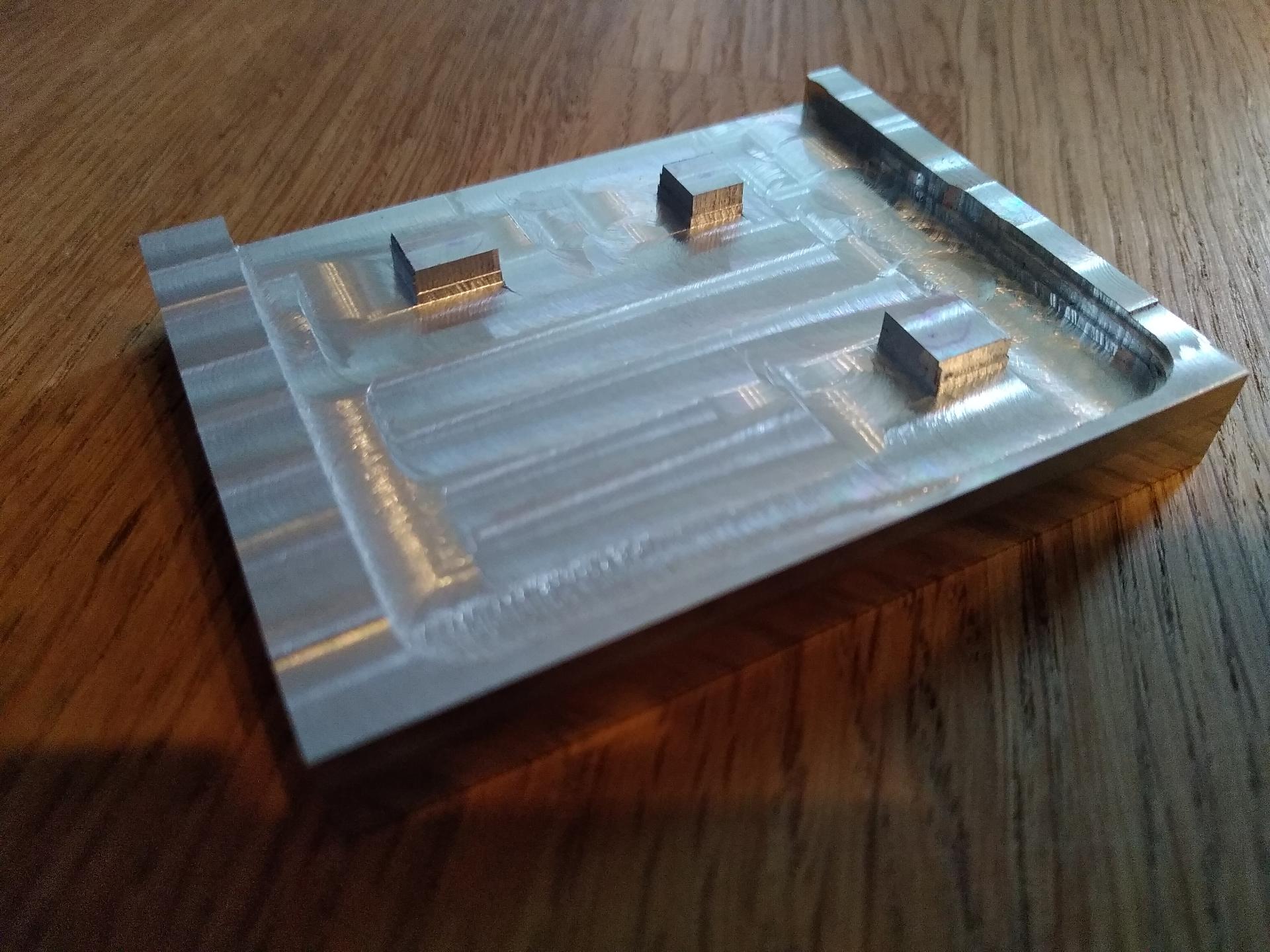

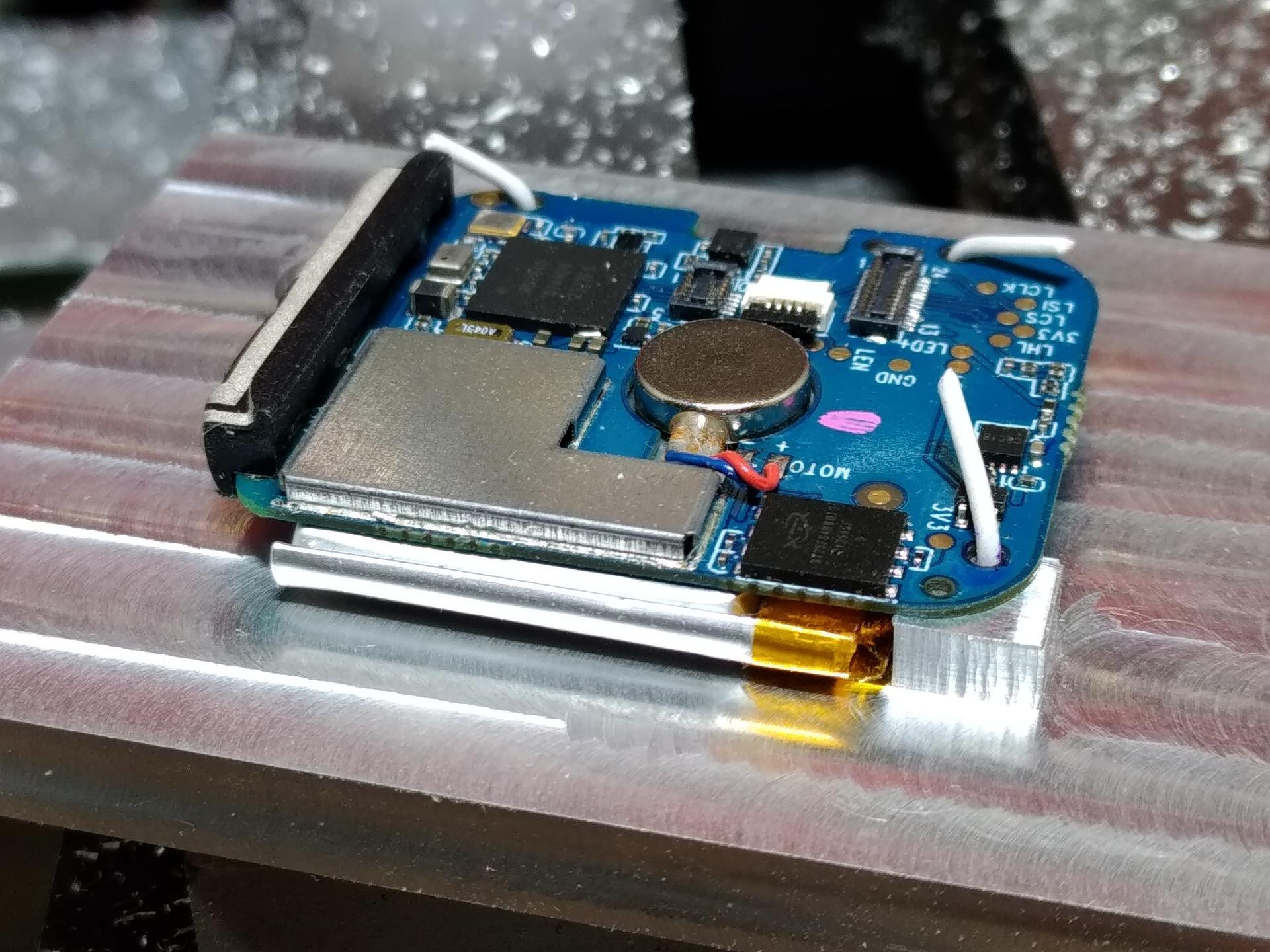

Thanks :) I cut down the top case a bit to get it closer the final dimensions and started carving out a bottom plate with material left for mounting the board.

4 Attachments

-

• #8

Hello @halemmerich,

have you made a bluetooth test with the bangle inside the aluminium Case?

Greetings

Minnten -

• #9

Not yet, but wrapping it in aluminium foil showed that it could work. Otherwise no way to tell how it will pan out with this dark magic RF stuff before I can actually close the case and screw it down 😉

If there are problems I can always cut some slots into the case and fill them with epoxy to try to get it to work. -

• #10

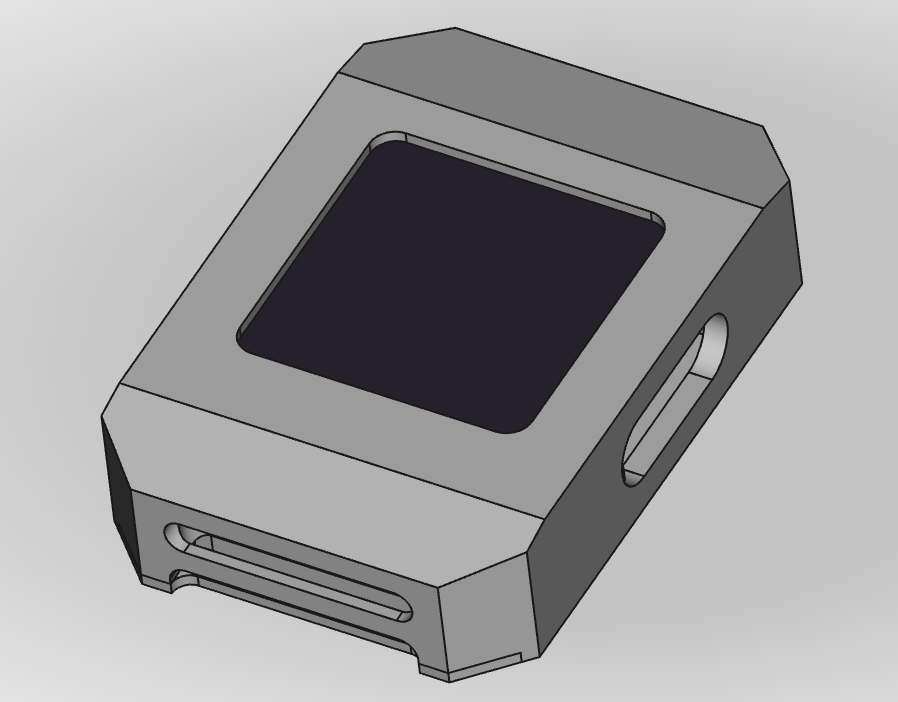

Some more changes on aluminium and CAD sides... Actually a bit of matching drawing to reality :)

4 Attachments

-

• #11

Wow, that's really starting to take shape now!

-

• #12

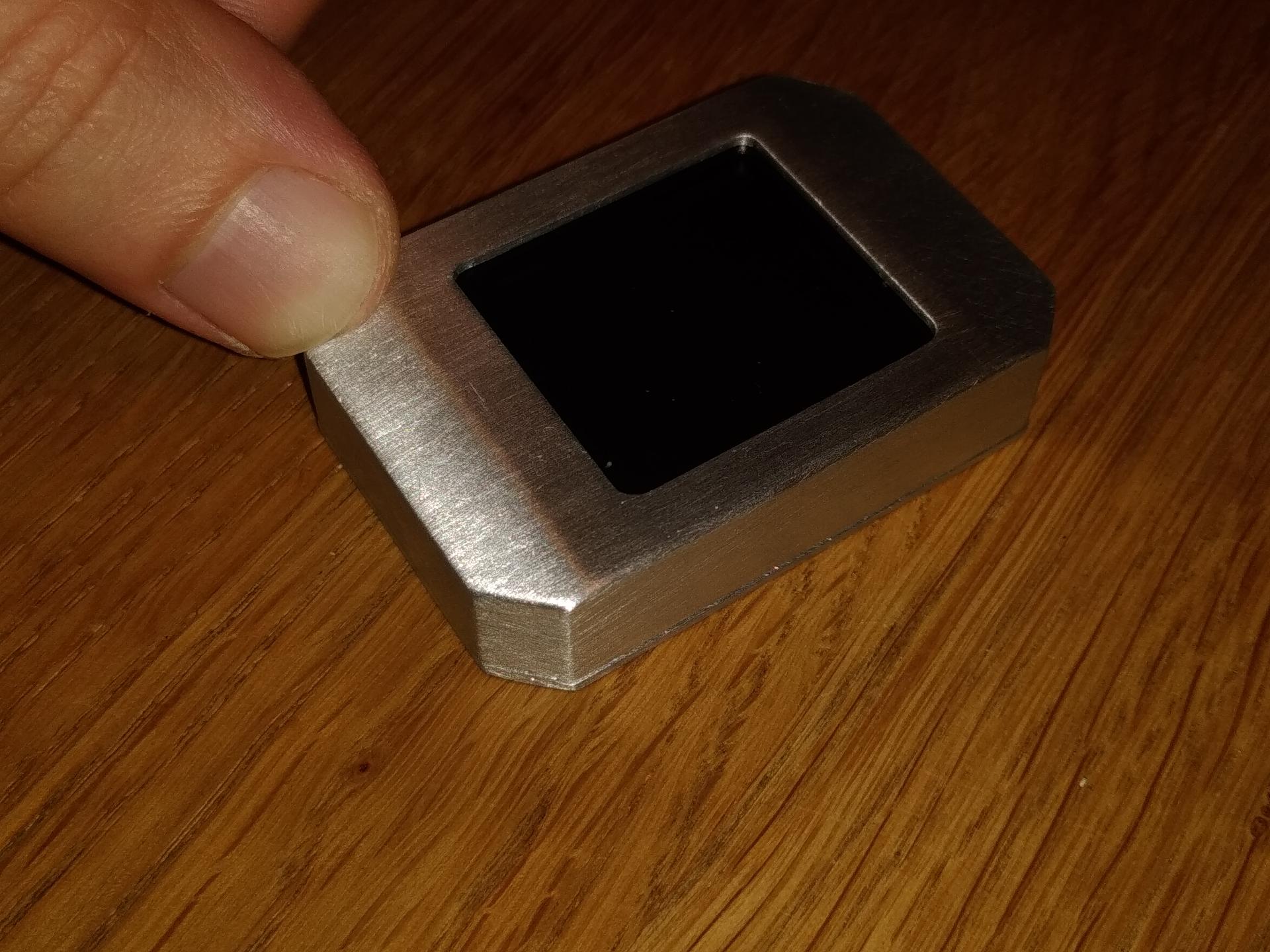

The overall shape is done (for now) and brushed over once just to see how it can look and before doing more I will have to wait on ordered M2 screws and a matching tap to hold it together.

I still need to find a solution for getting the button PCB attached and try out if my chosen method of getting a button in there will work at all. I think this will need one more build anyway, so this one is dedicated to experiments :)

5 Attachments

-

• #13

OK... after having broken this attempt while trying to drill and tap the screw holes the next one will not be manufactured by me. While I had fun doing this in the end my capabilities do not match my plans :D.

I have done a new design for some 3D print contractor to print (SLS/SLM) for me. No idea if this can work since I have absolutely zero experience with this but the custom case dream is not yet dead.

Features are still USB-C, more protection for the display and a bit more internal space for the battery while losing the HRM and a having decidedly chunkier watch. Additionally I will try to add an LED and an additional button to have a (dim) flashlight function for finding the way in absolute darkness.

2 Attachments

-

• #14

One of the coolest things i've seen posted on this forum. Look forward to see what it looks like when it finished!

-

• #15

The 3D print service (JLC3DP) accepted the file (warned me of thin walls but I took the risk) and it seems to be in production now. Scheduled to be sent out in 4 days. I have no idea what to expect but hoping for the best :) The whole thing was surprisingly affordable. About 13€ shipped in 316L stainless steel SLM.

Thanks to @Gordon for the detailed watch body file in https://forum.espruino.com/comments/17414317/. That will help me with designing a backplate that can house the HRM sensor. If I can get it out of the original case without destroying it...

-

• #16

About 13€ shipped in 316L stainless steel SLM.

That's insane! I'll have to try sending off some designs now :)

I just uploaded the exact file I provided in that last post and I'm quoted $8.36 + shipping for stainless. Potentially it's still quite a bit of work to swap out the aerial, HRM and charge connector (and the aerial is going to be no use inside the metal case anyway) but it's a very interesting option!

edit: I wonder what the tolerances will be like on it (it says 0.3mm which seems pretty good). In a way it's a shame it's not aluminium because then you could have finished off any mating surfaces with your mill - stainless is usually a bit of a pain to machine

-

• #17

This is amazing! I've got a little project to refurbish some 'heritage' window fittings at the moment - modelling them on my 3d printer - and this looks like the perfect service to get them fabricated properly 👍 (also a little bit jealous of your mill) 😀

-

• #18

I plan to glue the watch together with either low melt hot glue or B-7010 double sided tape to be able to take it apart relatively easily. The surface roughness might play to my advantage there.

PCBWay will do aluminium and stainless SLM for about 3 times the price. Even titanium for a bit over 100$. JLC3DP has nylon SLS options for even less money than metal SLM so that would solve the faraday cage problems. I'm currently hoping to just connect the whole case as aerial and maybe it works well enough to be usable. Probably not because the whole tuning will be completely out of whack, but we will see.

I will take some measurements and compare with the CAD file to post here when the thing arrives. There are some videos [*1] where the tolerances seem to be pretty nice. Better than 0.3mm at least.

If I loose GPS anyway because of the metal case, could I just remove the "antenna block" for more space inside the case or a slightly smaller case design? Or is it needed for other stuff as well? The barometer hole is on the same side in the original case.@Ivor: My mill is a set of old stuff I bought used for relatively cheap, Proxxon KT150 and BFB2000 (filled the pipe in the back with concrete) as the base and a Kress 1050 milling motor. It just about does aluminium well enough but it takes a lot of time doing this manually and it is very easy to make mistakes. If I had known how cheap 3D printing services had become I probably never would have tried to mill the case myself.

-

• #19

Cobbled a design together for the Backplate with space for the HRM using the file of the original one as reference. Seems to be thicker than I expected but I will see when I try to disassemble an HRM.

I placed the HRM slightly off center to account for the additional battery thickness. I do not think extension of the flatflex cable is doable in reasonable way.

I will try the case first without HRM and order the backplate when the next revision of the case itself is done after testing the current one. Production seems to be done and it should be shipped soon. It is even possible it arrives in time to tinker with on the weekend.

1 Attachment

-

• #20

@halemmerich that's a great project!

Maybe you can help me with your experiences with my own project. I am working on a project to make the bangle js 2 waterproof.

I decided to go buttonless because I fear the button is the main issue and many smart bands use the same approach. And it can easily be done by modifying the existing backcover 3D design. I already modified it and removed the button and barometer hole. Did you find a fully waterproof button?

Currently I am working on the software part to make the bangle js 2 and the existing apps useable without a button by sending "virtual" button events based on accelerometer double taps. It is partly working and looks promising.

Did you already dissassemble a bangle js 2? I only tried it with a magic 3 and it was easy with a fan but later I broke the display cable.

Is there a reason you decided to use usb charging? I hoped that the charging pins are easy and waterproof to glue and can be used for swd without opening the watch. Any idea where I can buy charging pins because I don't think I get them removed from the original bangle?

Thank you!

-

• #21

Just a quick thought - did you consider trying to make an outer case for the Bangle to waterproof it?

For example if you could get something printed in flexible rubber that went around the side of the Bangle and then you glued it on, that might allow you to waterproof it while still using the button?

-

• #22

Did you find a fully waterproof button?

I plan to use normal momentary switches and cover them in silicone. My design has 2mm deep cavities which should make for a few tenths of silicone over the button. That will hopefully be flexible enough to use the button and still hold up to daily use.

useable without a button

I had tried this by listening to the

accelevents and calling everything in the pin watches array for the button. Worked halfway decent but I did not want to modify the bootloader to make it work there as well so I decided to keep the button.Did you already dissassemble a bangle js 2?

Multiple Bangles, some of them multiple times :) My current way of choice for warming the Bangle up is a pot with a bit of simmering water and a flat top. My cookware has flat glass lids which get close to 100° with the steam from the simmering water. I just place the Bangle display down on the glass until it is hot enough. I have a heat gun with temperature settings but that has not worked as well for me.

Is there a reason you decided to use usb charging?

Multiple:

- More sturdy connection for charging in a bag

- One less cable to forget while packing for a trip

- Corrosion of the contact pads

- No idea how to get push-pins and magnets etc. aligned properly and waterproof :)

did you consider trying to make an outer case for the Bangle to waterproof it?

Maybe there is ABS as a very thin sheet or even film which could be "glued" over the button with acetone?

- More sturdy connection for charging in a bag

-

• #23

It is here and it is awesome! Ordered last Sunday, reviewed and payed for on Monday, delivered Saturday using the second cheapest delivery option.

Some things I have discovered:

- The contact pads for the push pins lift of the board really easy when soldered to -> use very flexible wire and support with some epoxy or something after soldering

- Stranded wire from an ethernet cable is nowhere near flexible enough

- My fingers are very big in comparison to a watch case

- Stainless SLM is awesome, width should have been 40mm and actually was 40.15mm

- Tiny holes in the drawing get even tinier in the end result. Planned 0.8mm for the wrist band mounting pins, got about 0.3mm. Widening them with a 1mm drill is no fun...

- Do not forget to plan tolerances for wrist band mounting stuff

- 1mm wall thickness seems absolutely fine

Watch body is 316L SLM and bottom plate is just 0.8mm stainless sheet, cut with tin snips and filed to match the body.

5 Attachments

- The contact pads for the push pins lift of the board really easy when soldered to -> use very flexible wire and support with some epoxy or something after soldering

-

• #24

Wow, that looks great!

Out of interest how is the touchscreen when surrounded by the stainless?

also, just interested but where did you get the watch from? Are they still for sale? Last I heard SMA weren't selling them any more

-

• #25

That is the "BT dead on arrival" for parts mainboard that you sent me a while ago. Since the board is unusable anyway I decided to use it as the first victim for trying to solder the USB-C port to. Good idea, since I ripped a pad of it straight away... The screen is also an old one which is somewhat broken so no real info regarding that until I use one of my actually working ones :) Will try that when there is less shoehorning going on.

Ganblejs

Ganblejs Gordon

Gordon halemmerich

halemmerich

HughB

HughB Minnten

Minnten

user156811

user156811 Ivor

Ivor

Chriz

Chriz

I wanted to have a go at FreeCAD and thought designing a case for the bangle would be nice to try out modeling something to actually build for the first time :)

Wishlist:

TODO:

Has somebody attempted something like this? I am sure this will take some iterations and probably fail in the end but no way of knowing without trying, eh?

I have an old manual proxxon desktop mill that can do about 0.1mm precision and some other tools and want to do this in aluminium.

I'll attach the FreeCAD file but be assured that it probably is not well done as I do not have experience with it or CAD at all.

5 Attachments