-

• #2

Sounds like a great idea. When we come up with a good design I'd happily get a bunch made at DirtyPCBs and sell them.

My personal preference would be for connected blocks of 3 pins. Maybe spaces for not just an SOIC8 but an SOIC16 too (on the other side?) and maybe slightly longer tracks to allow the SMD FETs to be soldered on too (that FET+SMD resistor thing is awesome).

Also if you're going for Pico support then a space for a JST connector (so it can be used with the Pico soldered down) and pads for a MAX1555 LiPo charger might make sense?

And mounting holes would be cool too.

-

• #3

I'd like edge headers in 2mm and 2.54mm pitch with a trace to a neighbour through hole pad (I.e exactly what the Espruino has on the edge opposite to the usb) so it's easy to route i/o to a header/plug.

Having a plethora of various SMD fooprints would be awesome too! For me the optimal would be to have through hole pads next to the smd pads (will constrain space though, and again this is so I could use jumper wires for quick prototyping).

Maybe it would be an idea to make two variants, one for SMD and one for through hole. It would also be cool to allow the protoboards to connect to eachother with say an edge connector and using the pcb as a plug into the next.

I have a lot of surplus SOT-23 and 0603 components, so thouse would be a high priority for me but probably not for the next guy.

Something like:

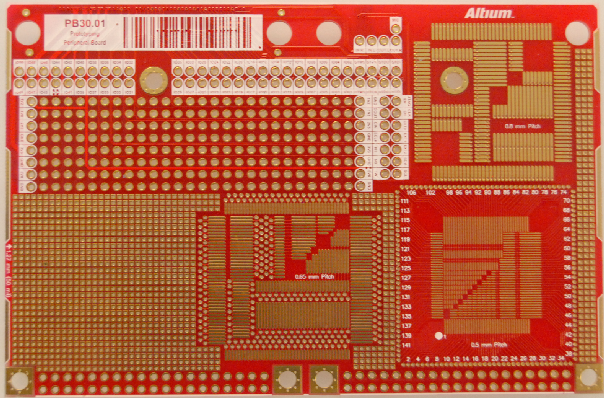

This board has a lot of options, and a nice way of doing multiple pin counts:

-

• #4

Another option is to have a 0.1" board (maybe with SOIC pads) and then have a second optional board full of snap-out adaptors that convert the more strange footprints back into 0.1"?

-

• #5

My thinking so far is for most of the surface to be stripes of two rows of 3 or 4-hole, each on either side of of SOIC pads (probably SOIC-16's, since 2 of those are an SOIC-8).

Note the extra pad at the end of the rows of 4 - that's an SMD pad... though maybe I should omit that, and just rely on the normal spacing, and let the SMD cover part of the last hole. I'll need to do a few mockups this weekend with printout.

There's also the question of whether to expose the copper between each hole in a row, and even whether to put that copper between the holes in a row on both sides, or only on one side - I think a trace could be squeezed between them - maybe for routing SPI or I2C? But maybe that wouldn't be a good place to route data lines. It would probably make sense to have some areas at least where there's 3 wires (SPI or I2C + spare) with multiple taps on it, near the IC area.

My plan is for there to be a hole for most, if not all pins - I don't want to make many assumptions about what specific part is going in any place, except for the most common-of-common (like a pile of SOT-23 with the sources all on ground or something).

I was thinking I need some spots with SOT-23-6 pads, maybe some of those weird SM-8 packages, thjat look like SOIC, only a bit smaller (I have a few parts in that).

Re: that red board - when was the last time you wanted to solder down something with pins on 4 sides, and it was something that would be sensible to slap onto protoboard? Sure, there are a million and one lovely sensors and stuff, but not in packages that you can really hand-solder onto protoboard.

I agree on some 2mm pitch near the edge for interfacing.

-

• #6

2x ssop-28 (back), 2x soic-24W/N + 2x msop16 (not a real package - I think msop stops at 10) with long pads for weird small stuff, three through hole per.

I think I'm going to have combo 5050 (like the leds) SOT-23-6 footprint, probably on the top (leds should point up, right?), with narrow SOIC on the back.

I'm going to have pads for esp8266 smd version, so the antenna hangs of the side (there will be rows of holes under it), like the end of the Pico has to)

-

• #7

Just stumbled upon this https://www.kickstarter.com/projects/658903329/perf-the-perfboard-reinvented some good ideas there I think :)

There's also a discussion here http://www.eevblog.com/forum/crowd-funded-projects/perf-the-perfboard-reinvented-**kickstarter-launch**/Though I'd post just in case you get some inspiration.

-

• #8

SOT23/5050 (top) SOIC-16 (bottom)

throughhole + espruino

SOIC24W/N, MSOP8(top) TSSOP-28 (bottom), ESP8266/RFM

Ground traces will be exposed, and have some holes in it (and will be on both sides). Those 0.1" gaps will have a Vcc trace.Somehow I need to cram in fets, interfacing, and some regulators in the remaining space.

-

• #9

Nice work man! I'll buy some off you if you plan on selling. Or order some if you release Gerbers. Looking good!

Would you consider breaking those 4-long rows around the Espruino into 2x2 with no solder mask between the two groups? Then it would be easy to lead f.ex a resistor over to some other device. And it would also be easy to make a solder bridge if one needs all three pins on an Espruino pin.

-

• #10

Good call. Done.

I will either sell them or release the gerbers, or maybe do DirtyPCB's $1 referral thingie. Or maybe @Gordon might be better placed to sell the Espruino ones. I think if these are good, I'll do a non-Espruino one (ie, for AVR/etc) with ISP headers for common AVR chips, and maybe TQFP pads for 328/1284. Would probably be easier to move.

Unless anyone sees any problems or room for improvement here, I'm going to send this off to dirtypcb's today or tomorrow, and I'm gonna do the non-shitty shipping I think, to get it in a reasonable length of time so I can assess whether to get a resellable quantity quickly.

-

• #11

Your power buses are floating? I guess you may be thinking that you wire them to where you want? (so there's no mask over? that's probably what the //// are all about....)

I would like to see a header exposing the lines from the pads of the power jack as well. For testing it would be nice to simply make a banana->jack and use a bench power supply. Currently it seems hard to do a direct tap?

Would you mind generating a 3d view (if your cad supports it easily).One more thing, if one wanted to do a large-ish LED project (and thus high current on the power jack) then thicker traces for it may be a good idea.

Lastly (if I were to sell something) I'd replace all straight angles with 45* like you do for most traces. If only to never hear anyone complain or ask why it's designed as it is. I'm sure it would have no practical implications but it might if someone wanted to make say an Espruino controller GPS Disciplined Oscillator.

Disclaimer: I am a beginner, think of these comments as questions.

Seems very good. I'd buy some.

-

• #12

Ya, the busses are exposed.

The power jack pins go out to sue of those rows of three near the jack.

I'll do a check for asymmetrical routing, but I'm not going to do Kickstarter, so I'm not too concerned. :)

Good catch on the trace width for power jack.

-

• #13

This is looking great, I'd be interested in grabbing some too. It'd be great for all the projects I'd like to try with surface mount parts, I've usually stuck with through hole up until now.

-

• #14

-

• #15

Looks great!

Just some ideas:

- those holes under the Pico will make it very difficult to solder a castellated Pico right onto the board - I guess you could just stick some tape under it to insulate it though?

- is there a cut-out in the board to allow a Type A USB socket to slide over the Pico? Looks like you've stopped the ground line there but the actual PCB outline goes straight on. Again, not an issue if you're mounting the Pico on pins, but if you want to solder it straight down it'd be a pain (and soldering it straight down is really handy).

- I don't know if you care, but you could swap all your square vias to be round with the 'Change' tool.

- I'm not sure where you'd put them, but what about mounting holes? A lot of people complained about that with Espruino, and I can see that you might want to screw it into a box

- Finally, I don't know whether there are 'standard' box sizes, but if there are, you might be able to tweak the PCB size slightly so it'll easily fit into a project box?

Looks like I'll probably start some kind of online shop for the adaptor shims, so I'd be very happy to sell this with some kind of referral?

About the 45 degree angles - I still think it's a non-issue for normal GPIO lines (I imagine it helps stuff like clock lines). But yes, it won't stop people complaining whenever they see one :) I still want a PCB design tool that'll do routing with nice curved lines that automatically bend around vias and things.

- those holes under the Pico will make it very difficult to solder a castellated Pico right onto the board - I guess you could just stick some tape under it to insulate it though?

-

• #16

Looking very good!

@Gordon "I still want a PCB design tool that'll do routing with nice curved lines that automatically bend around vias and things." Altium does this. You can either drag and it will place tracks according to rules where it can find path. You can also enable push tracks which will push tracks. Then push vias which will also push vias, lastly a god mode push which will replace everything to let your track through. It's powerful for tight routing!

https://youtu.be/VhPk3J1WcpE?t=4m11s

see it in action here (this guy uses 45* but you can change rules to use rounded (also min/pref/max radius). :)

EDIT: The link points to 4m11s [this is where you'll see via push] but it does not start from there here. Some bug with the autoembed I assume. (One more thing I'll fix if you make a branch of this forum :) ) -

• #17

Ohh, wow - that looks really neat (I love the via pushing - I've spent days doing that manually). But the price! There's no way I could afford that (and it's hard enough to find out what it is - it seems to be one of those "if you have to ask, you can't afford it" things!)

Looks like they do a community version, but I wonder how stripped back it is.

My idea was actually for smaller boards, to do some kind of spring/field-based routing. So to totally give up on the idea of straight lines, and instead just make each wire follow the path of least resistance. You could then just 'drag' wires inbetween the right pins, but the runs would be done automatically - potentially even letting parts themselves move around. I did have a go at a prototype myself, but I'll have to wait until I have some more time before it gets useful!

Anyway, I'm hijacking @DrAzzy's forum post :)

-

• #18

Holes under pico: They're there to make it more useful if you're not using a pico. My intent was for people to put tape there to insulate it when soldering it directly on.

Space for USB - Yipes! Good catch. I just removed all the exposed ground from that 1.2" section, and slid everything over 0.1", so, if you wanted people to laugh at you, you could plug the whole damned board into your USB port (assuming it's not recessed).

What square vias? <.< >.>

Mmmm.... Mounting holes... I'm not really sure where I could put them either!

I've seen no evidence of sizes of project boxes being standardized. They can't even decide whether to measure outside or inside.

@Gordon - we should probably talk about selling via PM/etc? I'm going to ebay a few of my initial protos, and see how they fly, and how much of a pain it is to ship them out. I think i might be able to just put them into envelopes and mail em like letters (at least w/in the US), in which case I'll probably be selling these, or at least the other version.

I will pull the trigger on a protopack of these in just a couple of hours - last chance to call out problems :-) I will have them shipped by a less-shitty shipping method, so I should have them in hand in a non-horrible length of time.

-

• #19

Space for USB - Yipes! Good catch. I just removed all the exposed ground from that 1.2" section, and slid everything over 0.1", so, if you wanted people to laugh at you, you could plug the whole damned board into your USB port (assuming it's not recessed).

Even 'it' is not recessed, usually there is other stuff connected right next to (one of the many) USB(s) where you could plug it. Then for putting it into a box or somewhere else, Pico's USB will stick out and make a waste of space for the rest of the board.

Acknowledged, it is not easy to meet all 'requirements'... could you think moving it and allow a breaking(cut)-0ut/away the area that a USB B connector would need when Pico is soldered to the board? - Yes, there would be some loss of prototype area / wholes, but in the end it would give a nice shaped overall boundary.

Just had the idea to provide two rows of the .5" places... they way the current layout shows, and another one inset for when Pico's USB 'tongue'-tip is flush with the board...

-

• #20

I'm going to ebay a few of my initial protos

Sounds like a plan - what about Tindie? That seems to be a great place for this kind of thing.

Yep, let's talk about stocking this off the forum - if I'm honest I'm probably going to be too busy to really think about/discuss this for the next 2 weeks though!

-

• #21

@allObjects:

I see your issue with the USB connector. I'm not inclined to mill out a huge notch, though - I could fit another row of 0.05" in, though at the cost of TWO rows of 4... I want to see how well that footprint works with production Pico's before I make decisions on this - I'm nervous about how hard it will be to solder it directly onto the board using the castellated pads - maybe will need to extend the pads, costing more board space and limiting options further.@Gordon:

Tindie? Isn't that a dating site?

But seriously, I've never bought anything on tindie - but everyone shops on ebay, and I figure, particularly for an AVR-centric protoboard - like with a pro mini outline instead of espruino, and maybe ISP headers pre-wired for 'x5/'x4/'1634 on the SOIC pads - I'll catch people looking for protoboard. Who the hell even uses tindie? I just asked a couple of friends, and they all said they had no idea.Since my protos won't get here for at least 2 weeks, I think that's a pretty reasonable timeline ;-) I'd like for someone to have soldered a Pico onto the pads and confirmed that that works before I order a larger batch.

-

• #22

Actually I remember posting your Picos out today, so hopefully you'll get them before you get the prototype :)

I don't know - I just see a bunch of stuff on Tindie... Having signed up for @bobricius's tiny little STM32 board I now get spammed with stuff - it seems like Tindie actively advertise their sellers products, which makes them more likely to sell (to whoever is signed up - maybe it's just me?).

But yeah, loads of people go on eBay - it just seems that most of what I see is stuff that's resold from China, not people's own work... but that doesn't mean things won't do well on there :)

There's always Amazon as well - and they'll even ship stuff out for you too.

-

• #24

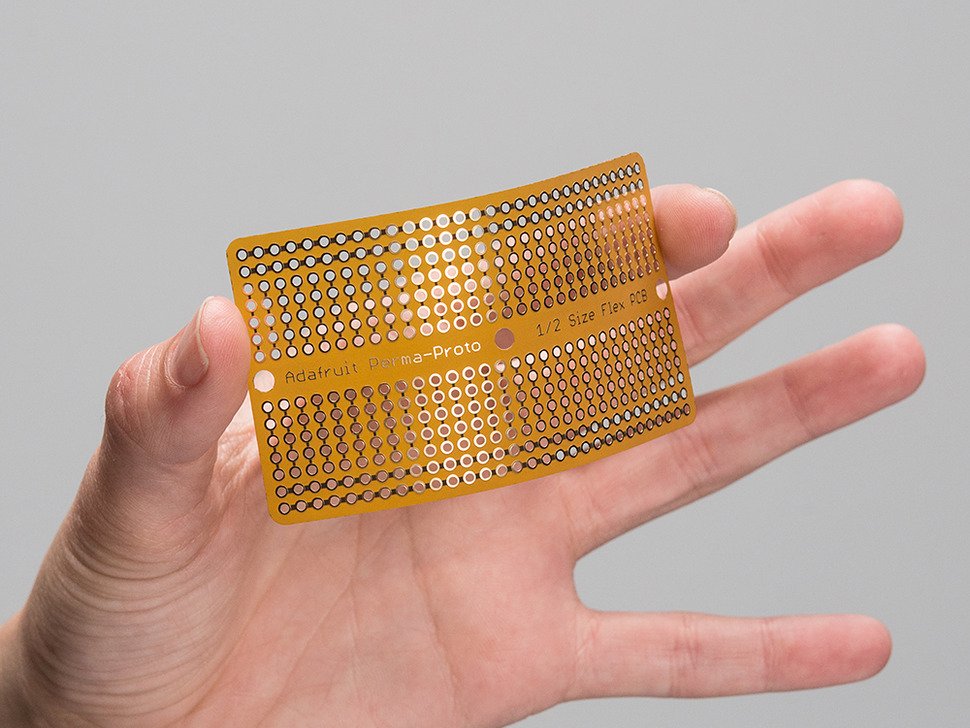

For simple projects, where you don't require anything beyond 0.1" pin spacing, one might consider the Adafruit Flex Perma-Proto - Half-sized Breadboard Flex-PCB. I really like that you can easily cut this to your required size with regular scissors.

It’s USD $7.50 as of this writing.

However, what if there was a flexible protoboard that also includes SOIC/SMC-compatible footprints, and that you could still trim to just the area needed by your required components?

There’s an opportunity to create an advanced revision of this, while continuing to allow gentle folding, so as to support development of most any tiny, embedded consumer product.

It could be Espruino-branded, yet also useful to – and compatible with – Arduino & Raspberry pi, while still promoting the Espruino platform to both professional and hobbyist embedded developers.

1 Attachment

-

• #25

Very few components like to be bent and stretched like that. Even solder joints can crack with repeated stress. Relying on the IC package for structural supports seems to me a bit backwards. I guess it's good for prototyping wearables, though I presume the project would die rather quickly.

Do you have experience using this? :)

EDIT: What's the progress on this @DrAzzy? Did you pull the trigger?

Gordon

Gordon alexanderbrevig

alexanderbrevig DrAzzy

DrAzzy the1laz

the1laz allObjects

allObjects oesterle

oesterle

So, we all build prototype-grade circuits...

Which means you end up building "on" something.

Most people who've used breadboard for a while quickly come to hate it for it's poor reliability (also odd things - apparently the capacitance is so high that some breadboard arduino's won't work unless you omit the loading caps on the crystal). Of course, any SMD stuff needs to be on breakout board. So breadboard, not so great.

Strip-board is better, but the kind with long strips requires you to cut copper with xacto-knives, and the result looks like utter shit. You're dependent on breakout boards for any SMD stuff, except that you can sometimes lay SMD resistors/caps between strips.

An even better kind is what I call "proto board" - this is like strip-board, but the strips are already broken up into groups of 4, so it's like breadboard. It may have traces running between rows of pins carrying power or ground.

I have some very nice protoboard from back when state of the art equipment was DIP parts, and that's how it was prototyped. What makes this nicer, is that it's double-sided, with plated through holes - this makes it better than most of the available protoboard. Ofc, same problem with SMD's.

There is also a garbage form of protoboard which has NO connections between the pins, so all it does is stick things down, so wiring is a nightmare. This stuff belongs in the trash. Unfortunately, is is VERY common.

Now, as it happens, Gordon has seen the light (as we all know very well; Espruino is awesome). Beyond that, also in prototyping, on the original board, with his integrated SMD prototyping area. Which is just wonderful, except for the little detail of it being attached to a $40 Espruino. My prototypes aren't that good ;-)

But imagine for a moment a hybrid prototyping board. This would have rows of pins in groups of 4 in some sections for general work and DIP stuff, but also some SOIC16 pads, with the pins broken out to strips with holes. Some SOIC8 ones too. Pads for some common transistors. Power and ground (maybe even an extra power rail) distributed around the board. The board could be designed so that "sections" with specific functions could be chopped off if not needed.

What has brought this to my mind again now is that DirtyPCBs will make 10 boards 10cm on a side (ie, just under 4x4) for $25. That's affordable, and a 4x4 hybrid protoboard would (designed well) make several devices.

What sorts of outlines and general considerations does this bring to people's minds?

Ideas on how to arrange things for maximum versatility for someone who works with both SMD and throughhole parts?

Obviously, it's going to have a pico header (using the pins, so you can use the space under it if the project doesn't call for a pico.

The motivation for this was the fact that it's pretty common for me to want, say, an SMD chip wired up to a few SOT-23's and some passives, with a regulator, and right now that's meant breakout boards and protoboard and ratsnests of wires, or me giving up and doing a home-fab board.

In the SMD areas, you could have different stuff on the two sides, too...... I like this.