-

• #2

Wow, that's a lot of work! Nice idea though being able to get extra components inside the case.

Interesting thought about adding another set of holes. It'd be pretty tight in most places, but A0..A5 are an option as you say. Perhaps just bare pads would be enough for most things?

I'm just about to get a new batch of Pixls assembled (all the PCBs are already made so it's too late for any changes) - do you think it's worth me getting a few made without the sockets soldered on?

-

• #3

The olimexinos have a second row in parallel with a sane .1" pitch all around so that you can use a perfo board. That's a good thing if you ask me. I would not solder the connectors, let the buyer choose whether to solder them or not, and where.

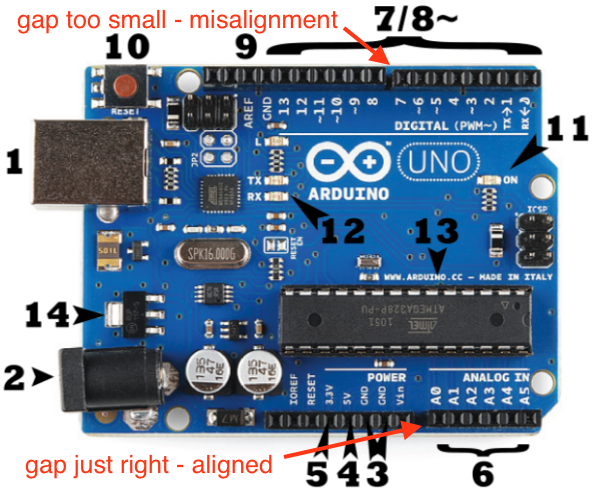

"The original Arduino design had a flaw and the connectors were not spaced at 0.1". This makes perfo board use impossible, so to keep the compatibility, we have the same spacing but we added next to this a connector on 0.1" which customers can use with perforated boards"

-

• #4

Pads help for sure... like in Puck.

I think it could be good thing to have socketed and unsocketed ones.

@Georg, the Arduino spacing issue on the pin 1..13 side is really bad. Some brute force may fix it: the headers on a clean 0.1" spaced carrier 'need some adjustments',...

I already used brute force 'technique' to get the 'legs' right: after soldering in the headers, take the insulation strip out and use some force, as I did with the ESP8266 ESP-01 to make it standard proto boards: breadboard friendly....

-

• #5

The connector that's a smidge misaligned is the one that carries GND and power iirc?

-

• #6

...nope, it is the one with the GPIOs... on the opposite side of where I added the internal connectors.

1 Attachment

Gordon

Gordon Georg

Georg allObjects

allObjects

For an upcoming project with a Pixl in an case, I need internal connectors to stay in Pixl's spirit: stay within footprint... also from the side... and at the same time keep Pixl the way it is.

Some soldering turned out cleaner. The side with for A0..A5 was a bit more challenging as you can see on the partially fried pin strip. The connector housings need also some modification that I performed using diamond files... btw. also very helpful w/ 3D printed things.

@Gordon, it would be nice to have extra through holes free for the pins - similar as in the Puck. I know, space is a challenge, at least for some of the pins, but for others it is not at all, such as A0..A5. Yes, I could remove the Arduino headers... but I intentionally wanted to keep them.

2 Attachments