-

• #27

Looks really good from what I can see - yes, picture upload is pretty strange. It might just be to do with the size (width and/or kBytes) of the picture?

If you email them to me (or stick them on GitHub) then I'll upload them though.

-

• #28

They are now on the GitHub folder:

https://github.com/yerpj/PixLcase/blob/master/1.jpg

https://github.com/yerpj/PixLcase/blob/master/2.jpg -

• #29

@Jean-Philippe_Rey, slick!

-

• #30

Printed it last night on a Prusa i3 MK3 @ 0.15mm with PLA.

Thanks @Jean-Philippe_Rey, it looks good! I would love to see an OpenSCAD version too..

1 Attachment

-

• #31

Great! The PixL.js logo is not bad at all, despite its small size.

Did you have any difficulty assembling it ? Did you notice anything that should be improved ?

-

• #32

It is a really tight fit in terms of assembly - I had to use a flat screwdriver to lift the corners in order to get them to close. Would one clip per corner instead of two maybe be sufficient?

I actually had to print the top part a second time, as it delaminated from the print bed at the corner where the logo is. This is mostly my own fault, as the first layer height wasn't calibrated correctly, but on the second print (with correct first layer height) it still lifted up from the bed a little bit. Maybe this could be resolved by moving the logo to the left by a small amount?

-

• #33

Maybe this could be resolved by moving the logo to the left by a small amount?

Probably having the logo on there makes it a lot more likely to delaminate anyway since the printer's having to do some quite detailed stuff on the lower layers...

It looks great as-is, but if the case extended over the black bit and edges of the display then not only would it detect the relatively delicate display controller under the black rubber, but you'd have a much bigger area in contact with the printer bed which might help to combat lifting as well?

-

• #34

--> https://github.com/yerpj/PixLcase/blob/master/preview_2.png

Would this new version address the current issues ?

(STL files already committed) -

• #35

Very cool - yes, I'd have thought so! I'll have to give it a go on my printer too (although the quality off mine really isn't great).

-

• #36

Whoops, just realized that buttons have disappeared... I'll check that

-

• #37

Here it is. STL files updated, this time WITH the buttons on both side.

-

• #38

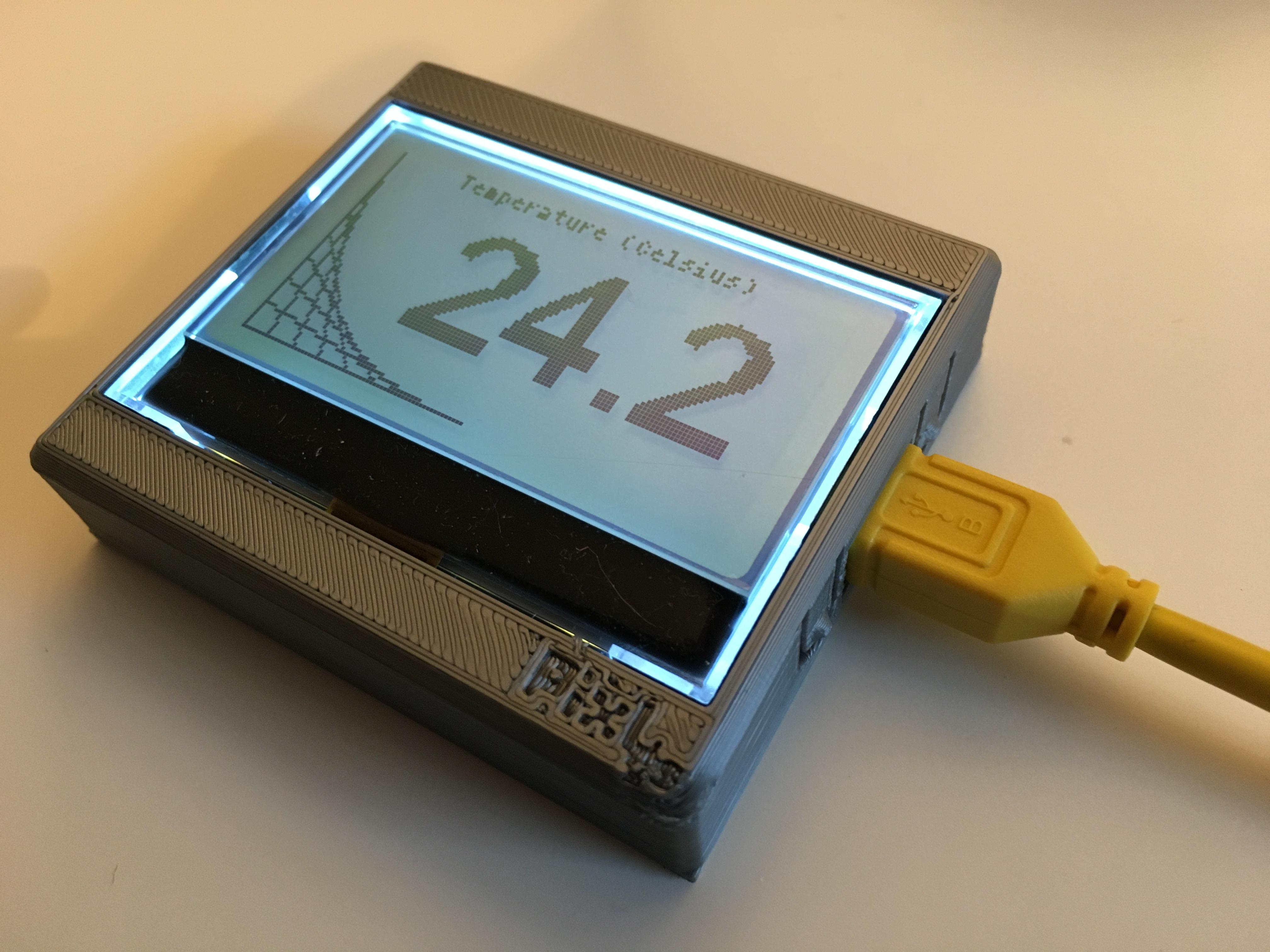

Nice. What's the light? Pixl doesn't have a backlight does it. If it does I'd missed that feature. Just an LED in there?

-

• #39

The led stand for the backlight ;-)

-

• #41

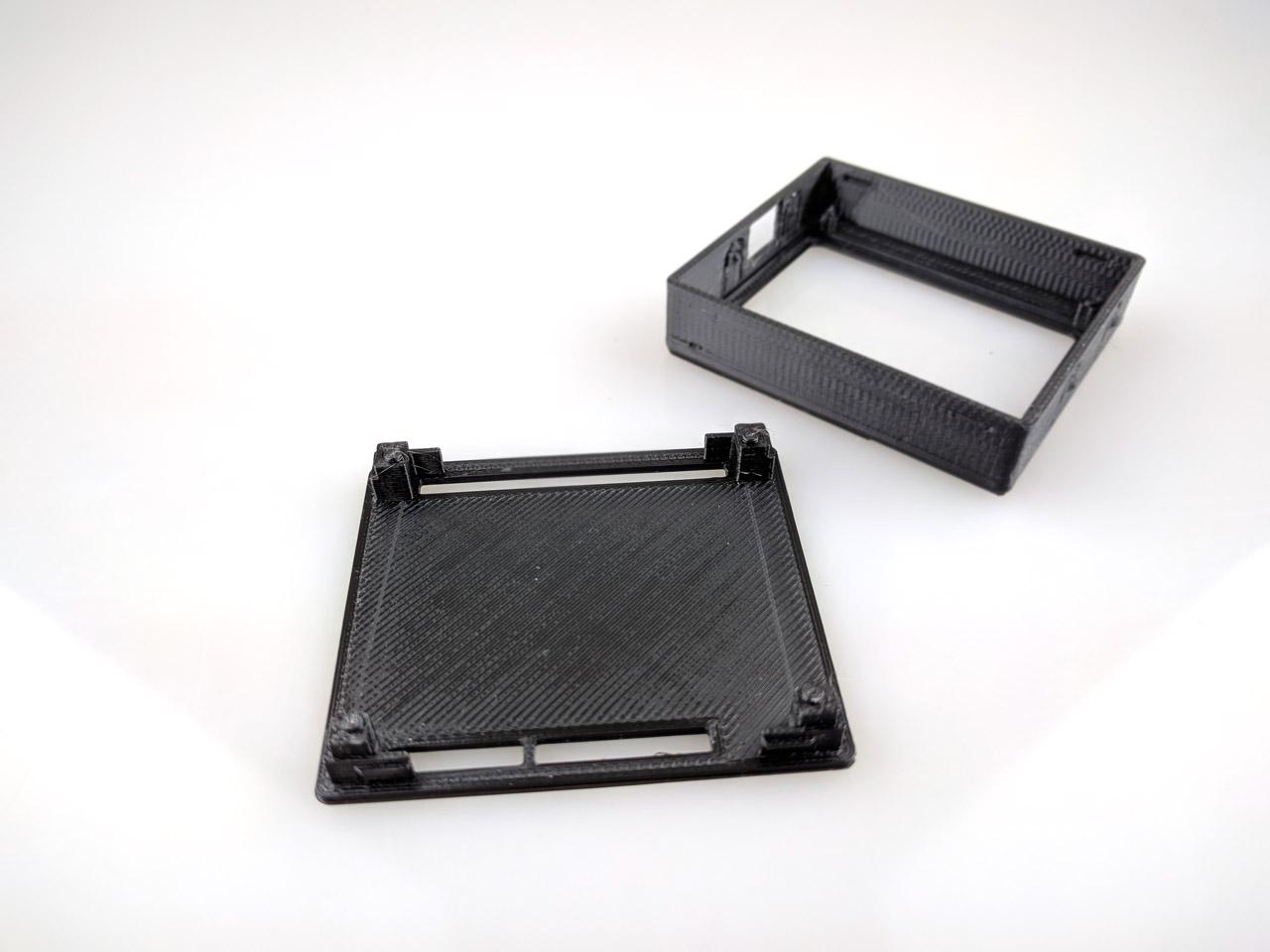

I found time to 3D-print the latest CAD model of the PixL.js housing. It fits pretty well around the PixL.js, the clips are easier to clip on and clip off, and the Display COG is now hidden behind the housing:

In case pictures are missing, you'll find them here : https://github.com/yerpj/PixLcase (PixLJs_1.jpg, PixLJs_2.jpg and PixLJs_3.jpg)

-

• #42

Wow, that looks awesome - thanks!

I should add that GitHub has a proper 3D viewer for STL files, so you can check out what the case looks like in 3D here

Getting these printed at i.materialise will cost around £22, and dirtypcbs charge around $22 (so 30% cheaper). Anyone else know of any cheaper 3D printing places you can send off to?

-

• #43

I'd bet 3Dhubs are competitive - though I've just tried to upload the STL to get some representative prices and it would not accept the files. I also can't open them in Cura? Just me?

It does look excellent though.

-

• #44

I downloaded again - fine that time.

3Dhubs - PLA 200μm layer height - £4.38 + £2 shipping (UK second class)

Europe shipping (tracked) is £10

-

• #45

Nice, thanks! Ordered - if this turns out ok I'll be using 3Dhubs way more!

Just a thought in terms of printability - you could always take away the 'bridges' in TOP_PixlJsCase that are at the foot of the buttons and over the USB hole, and move them into BOT_PixlJsCase. Might make it print easier on the more useless printers :)

-

• #46

I will do it

-

• #47

Just a thought in terms of printability - you could always take away the 'bridges' in TOP_PixlJsCase that are at the foot of the buttons and over the USB hole, and move them into BOT_PixlJsCase. Might make it print easier on the more useless printers :)

Thanks for the advice. I modified both parts accordingly.

https://github.com/yerpj/PixLcase/blob/master/BOT_PixlJsCase.STL

https://github.com/yerpj/PixLcase/blob/master/TOP_PixlJsCase.STL -

• #48

Nice - thanks!

-

• #49

Just got the print back from 3D Hubs - £8 delivered, just a few days later (it's with your older design, before your made those slight printability tweaks).

Everything clips in perfectly and it looks great, however they obviously printed both side by side so the texture of the front part changes when the rear finished printing :)

1 Attachment

-

• #50

It looks great anyway! cost+delivery time is very appealing!

Gordon

Gordon Jean-Philippe_Rey

Jean-Philippe_Rey allObjects

allObjects gendor

gendor

Ollie

Ollie MaBe

MaBe

I just uploaded the *STL files:

https://github.com/yerpj/PixLcase

I slightly adapted the 2-part housing in order to make it easier to assemble.