-

Honestly I wasnt even aware of this. Its great thing to learn about. I guess my implementation is just parallel.

If I get it right it would be enough to just move the rotation points on the T bar toward the middle. The problem with that would be that right now the T bar slides with the plastic screw on the stepper. If T bar gets tilted then it would get stuck?

Thanks for pointing that out. Thats interesting problem. I didnt send out the gerbers for fabrication yet.

As for the drivers I used TI drv8830 drivers for old implementation. This time I will go for LB1930 as they seem cheaper and more widely used for hobby stuff. They are used for one of espruino tutorials I think.

1 Attachment

-

Thanks for the feedback about the LB1930. I have something in the making with DRV8833 and two similar motors controlled by an MDBT42. I use a 3V cell for the MDBT42 and 4xAAA as power for the motors and auxiliaries. All is held together by some 3D printed pieces.

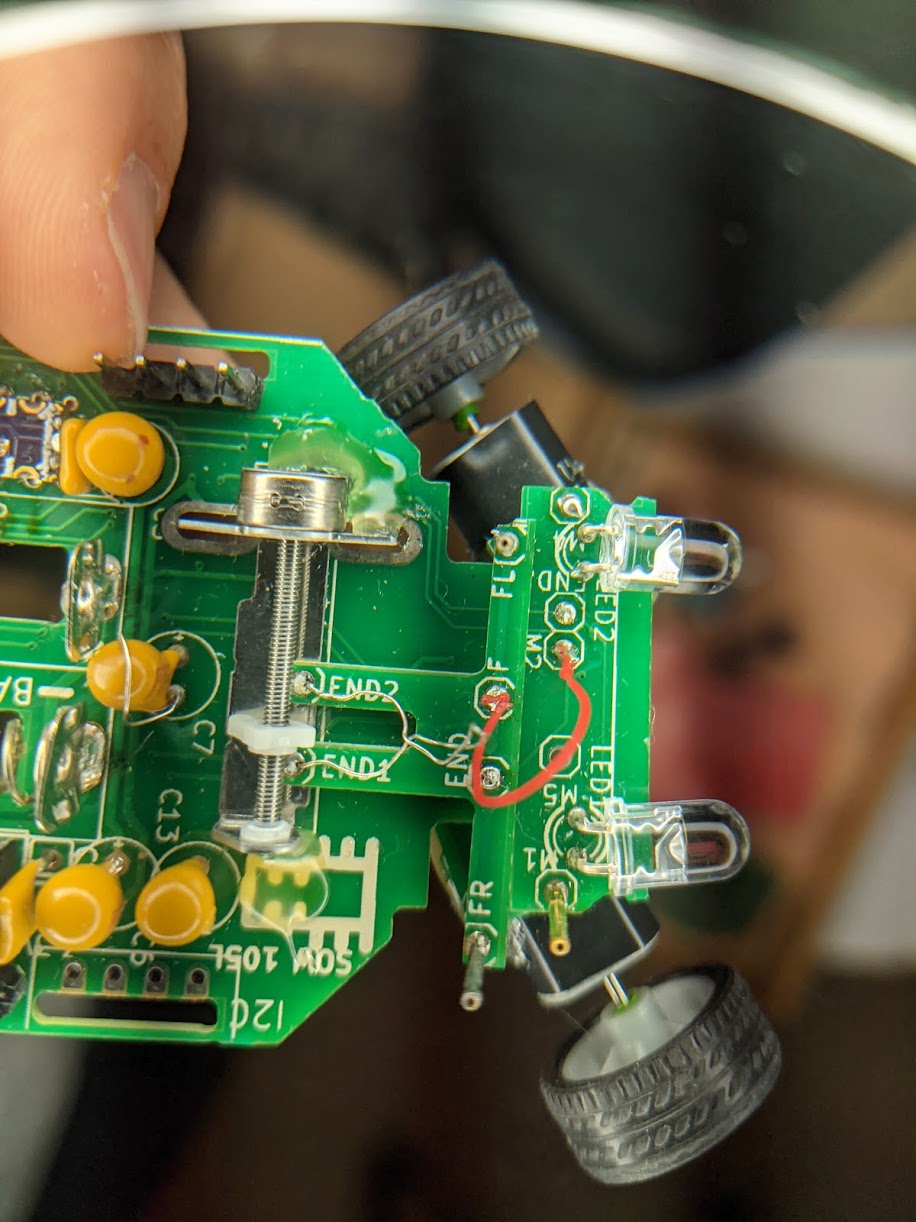

Using the PCB as the car chassis is perfect: fiberglass reinforced resin... (I once used a CD for a RC Car chassis). Very convincing are the pogo-pins for axle/turn, suspension springs and 'ball joints' AND electrical connection. Equally convincing is the setup of end-switches/detectors. Did you ever use them? ...or do you now on init just run the stepper 2 x max steering steps 'ramming' into end pos and then back to center with 1 x max steering steps? Do you have a trim on your controller for setting the center for straight steering?

Moving the vertical turn axis closer to the center plane of the wheel reduces the force on the steering. In cars it is even within the envelope of the tire... last but not least because the wheel-rim construction provides room / space and it is space saving (there is more to steering, but just having a 'perfect' angle for about 2/3rds of the left/right steering extent is usually more than the 80-20 gain-compromise with less than the usual 20 pain...

Btw, great detail picture of the front section with the steering.

Did you 'study' Lean Design / Construction / Engineering? (Could be a good idea to prep some kits and sell... for fun and hassle... :( )

kri100s

kri100s

allObjects

allObjects

I assume the wheel motor drivers are (ti?) DRV8833 Dual H-Bridge Motor Drivers.

With steering geometry I meant the following the different angles of the front wheels when in a curve... see attached pic... (and, for example, this link: https://gearcraft.blogspot.com/2011/11/steering-car.html). Ackerman (trapez) is geometrically better than just parallelogram. Davis is geometrically perfect but much more complicated to implement and has wear issues compared to the simply to implement Acherman setup (https://www.slideshare.net/jeetamrutiya1/steering-gear-mechanisms-kinematics-of-machines). The wear over time of the slides G, E, F and H demises the accuracy. Some current cars us a combination of slide (rack and pinion 'sliding' in E and F) connected with two link bars to the fixed-length and fix-angled levers (includes space saving), which could work nicely with your setup of the slider on the screw with driven by the micro servo.