-

• #2

Nice - thanks for posting it up :) Nice use of the Pixl board!

-

• #3

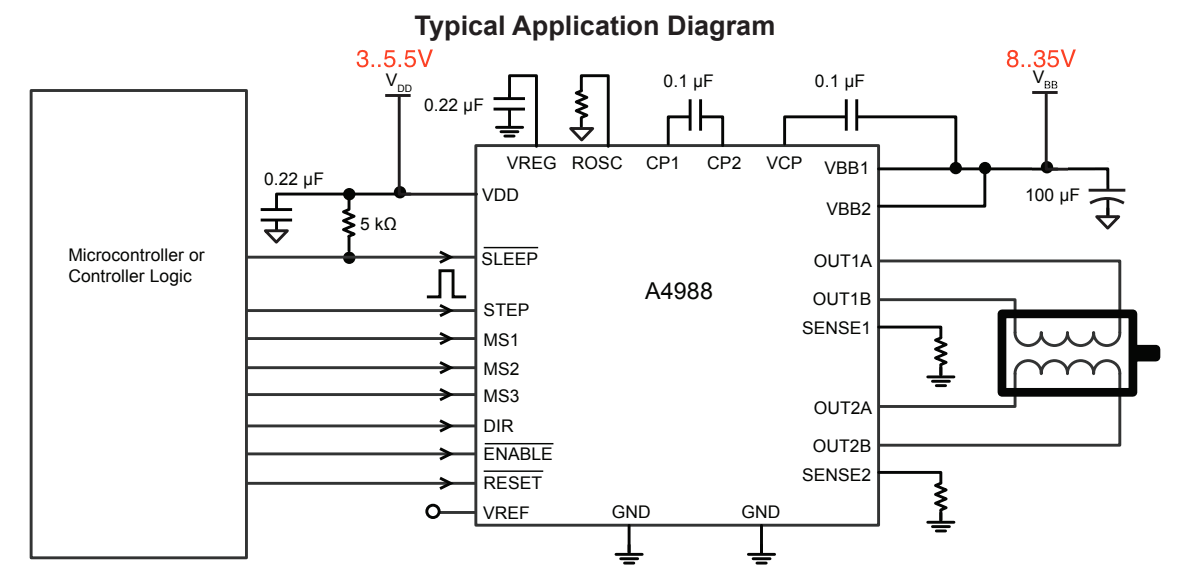

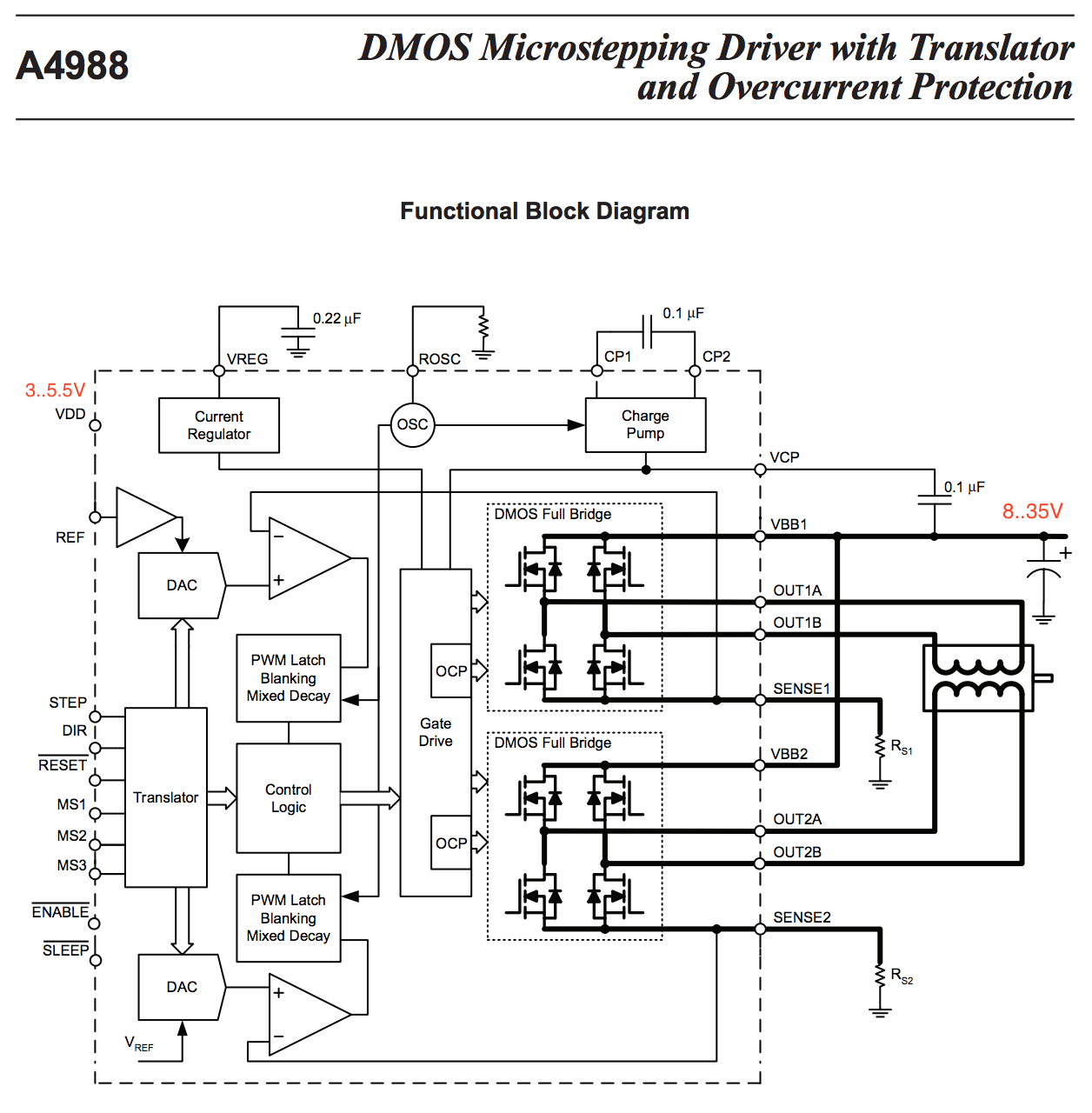

Was curious about the stepper controller that was used. …found the controller @ https://www.espruino.com/NRF52Stepper and https://www.espruino.com/modules/NRF52Stepper.js using the readily available stepper controller modules used by many of the 3D printers… the challenge I see is that they need constant attention by sending them pulses… Using internal PWM makes from a timing point 'bearable'…

You mentioned the stepper getting hot... The driver provides current decay... was the 50% rather than a few % duty cycle the issue that the decay did not kick in? -

I wonder why these controller chips are not a just a bit smarter and would understand commands like this: so many steps within this time frame. That would unload a central unit from a lot of work.

For details, see attached datasheet. Btw, there are chips that support for the power / stepper side also lower voltages than 8V... and higher current than 1.5A.

4 Attachments

-

• #4

Thank you Markus! I have just posted a reply to your comment on Medium, with some more details about my setup, as well as some information about stepper drivers that do support offloading the PWM generation from the main processor:

Gordon

Gordon allObjects

allObjects

urish

urish

I used a Pixl.js, a NEMA-17 Stepper motor and a KY-003 Hall Effect sensor:

The Espruino source code and 3d printed parts are available on github.

You can read the full story in the blog post I just published:

https://medium.com/@urish/improvising-hardware-diy-rotary-rock-tumbler-d3a1a1915ea9